The Best Products

Latest News

How do machining centers, engraving and milling machines, and carving machines differ?

1、 Conceptually speaking:

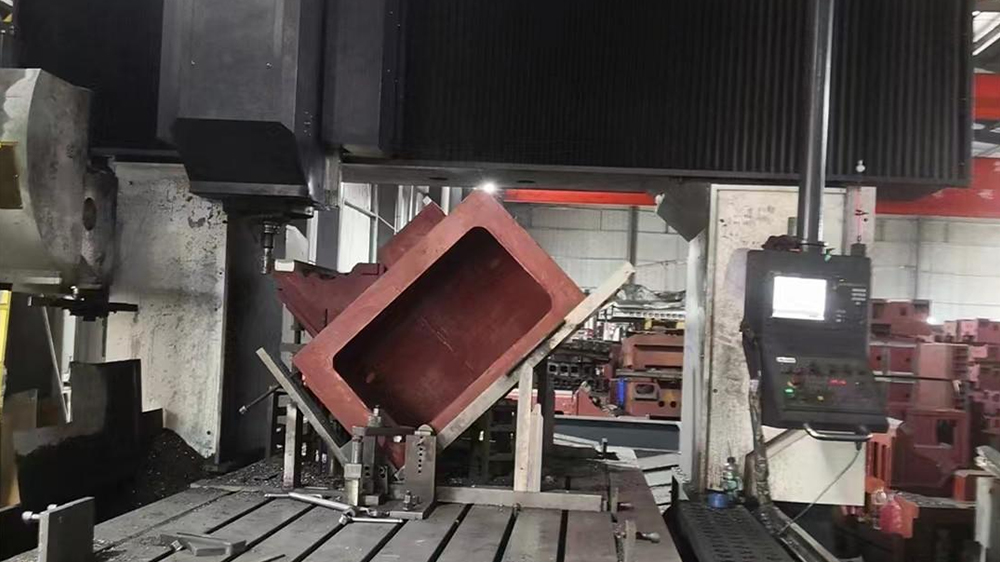

Machining center: It is called a computer gong in Hong Kong, Taiwan, and Guangdong, and is a highly automated multifunctional CNC machine tool with a tool magazine and automatic tool changing device. The first machining center was produced in the United States in 1958. It can achieve centralized processing of various processes such as milling, drilling, boring, reaming, and tapping after one clamping of the workpiece, with a special emphasis on the function of "milling".

Carving and milling machine: As the name suggests, it can carve and mill, and also increases the power of the spindle and servo motor on the basis of the carving machine. The bed can withstand the force while maintaining the high speed of the spindle, and more importantly, it has high precision. Carving and milling machines are still developing at high speeds, also known as high-speed machines, with stronger cutting capabilities, higher machining accuracy, and the ability to directly process materials with hardness above HRC60, forming them in one go.

Carving machine: The spindle speed is high, suitable for processing small cutting tools, but the torque is relatively small, focusing on the "carving" function. For example, wood (specifically for processing wooden boards, called wood carving machines), two-color boards, acrylic boards and other low hardness boards are not suitable for strong cutting of large workpieces. At present, most products marketed under the banner of carving machines are mainly for processing handicrafts, with low costs. Due to their low precision, they are not suitable for mold development; But there are also exceptions like chip engraving machines.

2、 In terms of appearance and volume:

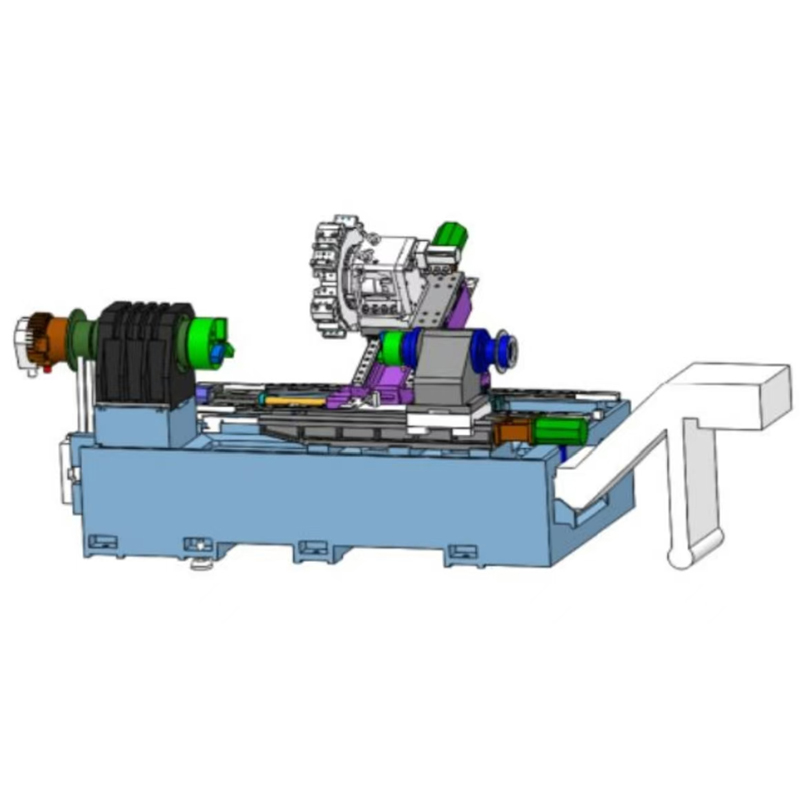

The machining center has the largest volume, with large machines on the market such as the 1690 machine having a volume of 4m * 3m, and small 850 machines having a volume of 2.5m * 2.5m. Baoma Company has also designed the BVMC-650 machine with a volume of 2.1m * 2.1m;

Engraving and milling machines are second, while larger machines on the market, such as the 750 model, typically measure 2.2m * 2m; Baoma Company also designed the BMDX120100 machine with a size of 2.7m * 3m for customer use.

The carving machine is the smallest, about 1.8m.

3、 From a mechanical perspective:

Vertical machining centers generally adopt cantilever structures, while carving and milling machines and engraving machines generally use gantry structures, which are further divided into beam type and fixed beam type. Currently, fixed beam type is the most commonly used for carving and milling machines.

4、 From the perspective of indicator data:

Maximum spindle speed (r/min): The machining center speed is generally around 12000; The most common speed for carving and milling machines is 24000 revolutions per minute, and the lowest speed for carving machines can reach 30000 revolutions per minute; Carving machines are generally the same as engraving and milling machines. Carving machines used for highlight processing can reach 80000 revolutions per minute, but they do not use ordinary electric spindles but air floating spindles.

In terms of spindle power: the machining center has the highest power, ranging from several kilowatts to tens of kilowatts, and also has the highest torque; Engraving and milling machines are second, generally within ten kilowatts; The carving machine is the smallest and has the smallest cutting capacity.

Cutting quantity: The machining center has the largest cutting capacity, making it particularly suitable for heavy cutting and rough cutting; Next to carving and milling machines, suitable for precision machining; The carving machine is the smallest.

In terms of movement speed: Due to the relatively lightweight nature of engraving and milling machines and carving machines, their movement speed and feed rate are faster than machining centers, especially for carving machines equipped with linear motors, which can reach a maximum movement speed of 120m/min

In terms of processing accuracy: the accuracy of the three is similar.

5、 In terms of processing dimensions:

The workbench area can better illustrate this point. The minimum workbench area (in millimeters, the same below) for domestic machining centers (computer gongs) is 850 * 520 (BMVC650 machine); The maximum worktable area of the engraving and milling machine is 1050 * 1300 (BMDX120100 machine), and the minimum is 420 * 600 (BMDX5040 machine); Carving machines generally do not exceed 450 * 450, with a common size of 45 * 270 (250 machines).

6、 From the perspective of application objects:

Machining centers are mainly used for processing workpieces with large milling volumes, large molds, materials with relatively high hardness, and are also suitable for roughing ordinary molds; Carving and milling machines are more suitable for completing small milling volumes and precision machining of small molds, and are suitable for processing copper, graphite, and other materials; Low end carving machines tend to process non-metallic sheets with low hardness such as wood, two-color boards, and acrylic boards, while high-end ones are suitable for polishing and grinding chips, metal shells, and other materials.